What is resistor?

Resistor

is a component that is used in electronic circuits and electrical networks to

primarily resist flow of current. It is

a passive component with two (or more) terminals and of variety of types as per

functions. The latest SMD resistors have

no leads but contact surfaces to connect electrically. According to Ohm’s law, in a DC circuit, (and

also in AC circuits, in case of pure resistance) the current through a resistor

is inversely proportional to its resistance, and directly proportional to the

voltage across it. Typical

applications and uses of resistors are: to reduce current flow, adjust signal

levels, to divide voltages, bias active elements, dissipate electrical power (as heat).

Resistor Value calculation, naming, colour codes and symbol

Resistors

are defined in terms of its resistance value in Ohms (or in Kilo-Ohms –

K). Also, rating of resistors is defined

in terms of watts. Resistor size changes

with variation in watts value for same value of resistance Wattage of resistors

varies from 1/8th W to few kW depending upon types). There are various ways of mentioning resistor

value and one way is by colour codes.

There are 3 or more colour bands with one band for tolerance and accordingly

value in terms of Ohms for any resistor can be defined. Details are in attached image.

Another

important factor associated with resistor value is its tolerance, i.e.

permissible variation in actual value.

Resistors with tolerance of 1% or less are used in precision electronic

circuits and these are depending upon their structure, like MFR or CERMET

resistors.

SMD

resistors have different methods of calculation of their values. Because of vary small size of SMD resistors,

they have a different system of coding. The most commonly seen codes are the

three- and four-digit system and an Electronic Industries Alliance (EIA) system

called EIA-96.

There

are resistors with zero (0) value also to be used in specific applications.

Types of resistors

Resistors are produced with a wide variety of

materials and manufacturing processes. Each resistor material has its typical

properties and specific areas of use. The main types that are used in

electrical engineering are summed below.

ü Wire wound (WW)

The wire wound resistor is

made by winding the metal wire around a metal core. In wire wound resistors,

metal wire is used as the resistance element and metal core is used as the

non-conductive material. Normally the

resistive wire is insulated, so that adjacent wires do not short together.

A Nichrome or

Manganin is commonly used as the metal wires, because they provide high

resistance to the electric current and operates at high temperature. Most

commonly used core materials include plastic, fiberglass, or ceramic.

Wire wound resistors were one of the

first types of resistor to be manufactured in the earliest days of electrical

science and then wireless. They were superseded in many applications by carbon

resistors and then metal oxide and metal film resistors. However, today, wire

would resistors are still used as the resistor of choice in many applications.

ü Carbon Composition (CCR)

Carbon composition resistors (CCR) consist of a solid

cylindrical resistive element with embedded wire leads or metal end caps to

which the lead wires are attached. The body of the resistor is protected with

paint or plastic. These resistors are the most commonly

used resistors in the 1960’s and earlier. However, now-a-days, carbon

composition resistors are rarely used because of its high cost and low

stability. The carbon composition resistors are also called carbon composition

or carbon resistors.

ü Carbon Film (CFR)

Carbon film

resistors are a significant improvement on carbon composition. However, in

comparison to metal film and metal oxide film, the commercially available range

steadily decreases. Metal and oxide film are not more expensive to produce, and

have overall better properties. Carbon

film resistors are a fixed form type resistor. They are constructed out of a

ceramic carrier with a thin pure carbon film around it, ( The carbon film is

deposited on a ceramic former) that functions as resistive material.

ü Metal Film (MFR)

Metal film

resistors have a thin metal layer as resistive element on a non-conducting

body. They are amongst the most common types of axial resistors. Other film

type resistors are carbon film and thick and thin film resistors. In most

literature referrals to metal film, usually it is a cylindrical axial resistor.

However, thin film chip resistors use the same manufacturing principle for the

metal layer. The appearance of metal film resistors is similar to carbon film

resistors, but their properties for stability, accuracy and reliability are

considerably better.

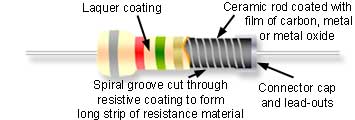

ü Metal Oxide Film

Metal-oxide film resistors are made of ceramic rod that

is coated with a thin film of metal oxides, such as

tin oxide. Metal oxide film resistors must not be confused

with metal oxide varistors, made of zinc oxide or silicon

carbide. Metal Oxide Resistors belong to the family of fixed form

axial resistors similar to metal film resistors and carbon film resistors.

Instead of a metal film, these resistors use a metal oxide resistance material

that is coated on top of a ceramic substrate.

ü Foil

The metal foil resistor has the best precision and stability

properties of all resistor types. The foil is made of an alloy of usually

Nichrome with additives. It is mounted on a ceramic carrier with high heat

conductivity. The foil has a thickness of only several micrometres. The desired

resistance value is achieved by a photoetched resistive pattern in the foil.

The metal foil resistor has a low Temperature Coefficient of Resistance (TCR),

good long-term stability, low noise, low capacitance, fast thermal

stabilization and no inductance.

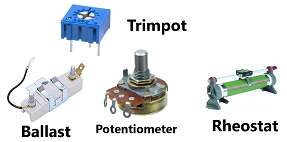

Depending

upon material, construction and applications, resistors are available in

different types, such as:

Ø Fixed resistors

Ø Variable resistors, like:

§ Potentiometer

§ Rheostat

§ Trim

pot

§ Ballast

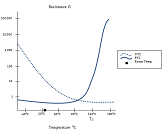

Ø Resistance dependent on a special characteristic:

§ Thermistors (NTC and PTC) as function of temperature change

§ Photo resistor – Light Dependent Resistors (LDR) value changing as per changing

light level

§ Varistor

– Voltage Dependent Resistors (VDR) value changing as per changing voltage

§ Magneto resistor (MDR) changing

as per magnetic field

§ Strain Gauges

value changing with mechanical load

How resistors are manufactured?

Resistors can

be constructed out of a variety of materials.

Manufacturing process and technology differs with type of material and

construction. Most common

modern resistors are made out of either a carbon, metal, or

metal-oxide film. In these resistors, a thin film of conductive (though

still resistive) material is wrapped in a helix around and covered by an

insulating material. The

process involves depositing a film of resistive material such as tin oxide

on a tiny ceramic chip. The edges of the resistor are then accurately

ground, or cut with a laser to give a precise resistance (which depends on the

width of the resistor film), across the ends of the device. Exact elaborate processes of manufacturing,

however will differ from resistor type to type.

New about resistors

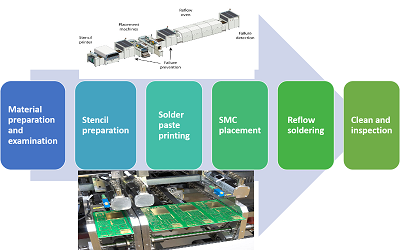

SMD (Surface Mount Devices) resistors are new in the technology

upgradation of resistors. SMT (Surface Mount Technology that uses SMD components) was

invented to both reduce the size of components and significantly reduce the

time it takes to manufacture a circuit. SMDs, are essentially very small

size resistors but without leads, are mounted on PCB surface and are connected

in circuit in wave soldering process.

SMT manufacturing is a new technology with many advantages of

manufacturing including accuracy, speed and quality.

.jpg)

CREDITS: Resistor Guide, Wikipedia, Manufacturers

websites

This is a brief overview of this topic. The subject itself is vary vast and it’s not

expected to cover every aspect here.

Technical details in this article are compiled from best known

sources. These are of course open for

any corrections and additions.